V-Band style clamps – also commonly known as V-Clamps – are used frequently in both the heavy-duty and performance vehicle market due to their tight sealing capabilities. The V-Band clamp is a heavy-duty clamping method for flanged pipes of all kinds. Exhaust V-Clamps and V-Band couplings are the most common and are known throughout the industry for their strength and durability. V-Band clamps are also found in many industrial applications as they are extremely resistant to corrosion in harsh environments.

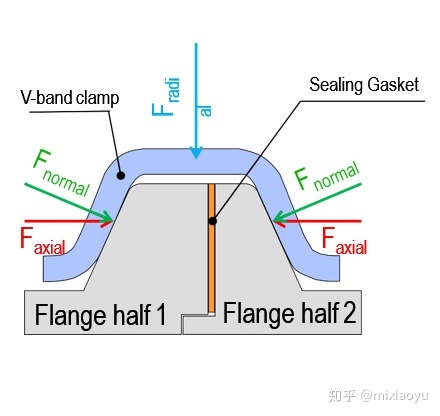

Connection principle of V type clamp

The V Band Pipe Clamp is tightened by bolts to generate F (normal) force on the contact surface of the flange and the V-shaped clamp. Through the V-shaped included angle, the force value is converted into F (axial) and F (radi).

F (axial) is the force to compress the flanges. This force is transmitted to the gasket between the flanges to compress the gasket and form a sealing function.

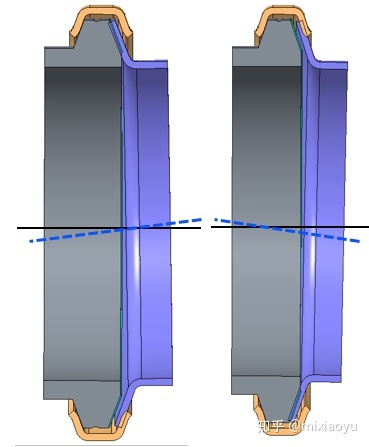

Advantage:

Due to the machining of the flange surfaces at both ends, a very small leakage rate (0.1l/min at 0.3bar) can be achieved

Installation is very convenient

Disadvantages:

Because the flange needs to be machined, the cost is higher

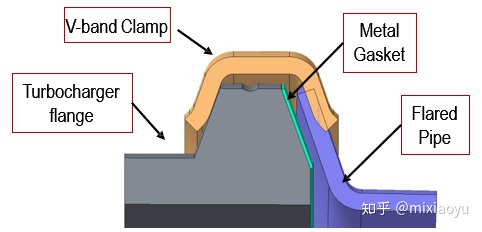

2.One end is machined flange, the other end is formed bell mouth tube, and the middle is metal gasket

Advantage:

Since one end is a molded tube, the cost is relatively cheap

When the two ends are connected, a certain angle can be allowed

Disadvantages:

Leakage rate <0.5l/min at 0.3bar)

Post time: Dec-25-2021

Whatsapp:+86 15222867341

Whatsapp:+86 15222867341